A The main features of the machine tools

1, spindle bearings double row cylindrical roller bearings and angular contact bearings, the combination of, subjected to constant force load pretension, good rigidity and spindle

2, feed and compensation by AC servo motor to achieve a low backlash deceleration driven ball screw, feed, and compensation for accurate

3, the grinding process, the workpiece in the grinding wheel middle for reciprocating movement, high precision grinding

4, two-wheel advance and retreat movement rail to pay for the "cross" roll rails, support, good rigidity, high precision response

5, the reciprocating motion with a short cylindrical linear roll rails, flexible movement

6, Dresser arm pairs a revised form of reasonable structure, easy to achieve the desired wheel shape

7,90 ° rotation operation box accompanied by a 10-inch color touch screen, the operation will be simple

8, the installation of the inverter can achieve differential grinding

B The main technical parameters of the machine

| roject |

Machine specifications and configuration |

| Spindle motor |

45KW × 2 low vibration, low noise motor |

| Control system |

Mitsubishi electrical control system |

| Feed motor |

1.5KW × 2 Mitsubishi AC servo motor |

| Touch screen |

10-inch color touch screen |

| Spindle |

Spindle used P4-bearing |

| Spindle used P4-bearing |

Reciprocating grinding

|

Workpiece diameter φ 300 mm ~ φ 800 mm |

| Workpiece height H60 ㎜ ~ H300 mm |

|

Tooling plate grinding

|

Workpiece diameter φ 800 mm ~ φ 1600 mm |

| Workpiece height H35 ㎜ ~ H200 mm |

| Grinding precision |

Parallel degree ≤ 8 μ m |

| Curvature ≤ 8 μ m |

| The roughness Ra0.63 Ra0.63 μ m |

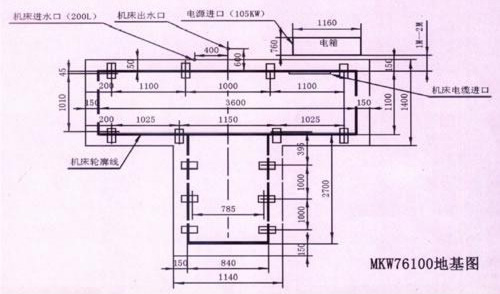

C The MKW76100 foundation plans

|